Back when I was much younger than I am now, I worked in many temporary jobs to support myself during higher education. Warehouses, bakeries, kitchens and hospitals, to name a few of the places that I worked.

I am above average height, so I soon became aware that many of the fixtures or tools I was expected to use were too small for me. Even in this day and age, items such as vacuum cleaners, mops and sinks are designed with the assumption that they will be used by average-sized women rather than persons of my size.

In many of the places where I worked it was not uncommon to see broom-handles extended with a length of pipe. Sadly many other tools were not so easily adapted.

A Little Off the End

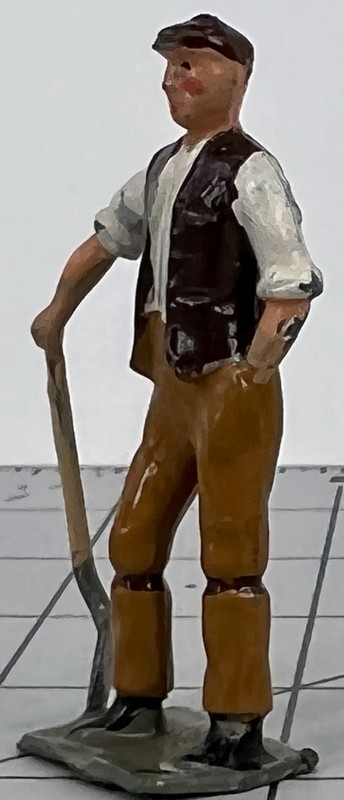

Recently, someone was describing to me their early working life as a labourer on building sites.

“One of the first things you would do is shorten your shovel by an inch.”

Given my own early working background, it may not be surprising that I could not resist asking: “Which end?”

It turned out, it was not uncommon to shorten the shovel [spade] blade and resharpen the new edge.

Resharpening the edge made the tool more efficient and negated any neglect that a previous user might have inflicted.

It also lightened the shovel a few grams, and if you were expected to use a shovel all day, this weight saving was considered to be significant and worth having.

Of a similar ilk, cleaning the tool at the end of the day was considered important. A few millimetres of concrete drying on the shovel would add weight and make the shovel harder to use the next day.

This rather reminded me of the old adage about an ounce on the feet being like a pound on the back. A slight decrease in shovel weight may significantly decrease fatigue.

Less is More?

Logically, a shorter shovel/spade blade results in a smaller volume of material that is moved by each shovelful. Less volume means less mass, so each shovelful/spadesful took less effort to move. Thus a small decrease in blade-size might mean a significant reduction in energy needed to move each spadesful, since each spadesful would be lighter.

Of course, to move a given volume would take more actions with a smaller blade, but that may be more practical than moving it as a smaller number of much heavier loads. Are half-a-dozen light loads easier to move than three that are twice as heavy?

The following diagram may not be familiar unless you work in safety, or injury liability. It shows the recommended maximal loads that should be attempted by an average male or female.

Maximum safe lifting is with the load close to the pelvis. The further the load is from this point, the less that can be safely lifted.

About 37% of work-related injuries are due to poor manual-handling practices, with a surprising number occurring in office and “white-collar” environments.

Based on the above, a shovel/spade-load and the tool being used to lift it should be around no more than 5 to 10 kilos in total mass.

In my blog on “Easier Entrenchment”, we encountered accounts of 19th century soldiers throwing up useful earthworks using trowel-sized bayonets. A narrower blade should penetrate packed earth better. Specially designed trenching shovels tend to have long heads than may be only four inches/100 mm wide. Very different from the modern, issued entrenching tool!

Can a smaller, more efficient shape make that much difference?

All this suggests the basis for a really useful time-and-motion or ergonomics study.

What is the most effective way to throw up an earthwork with manual tools?

If the work is easier made in smaller rather than larger bites, what is the optimum size and shape of shovel blade?

I notice that some of the titanium tools on offer on the internet are not just lighter, but use blades of 200 x 90mm dimensions on a 64 cm haft.

What is the best configuration and length of handle for a typical male?